Oh that sweet, roasted aroma that can wake up a sleeping giant.

That warm, bittersweet liquid that is brewing in the machine. The crushed beans releasing its intoxicating essence into the boiling water.

That cup of coffee is sometimes all that is needed for a lot of people to get their day started.

But before that bean becomes the coffee powder we love so much, it had to go through a lot of, shall we say growing pains, before making its way into our coffee cups.

To begin with, growing coffee trees is not an easy process.

The beans or coffee cherry begins its life as all other fruits do, like a flower. The crowd favourite, Arabica coffee beans, are self-pollinating making it the preferred bean to grow. The Robusta plants, on the other hand, need insects or the good old wind to get them pollinated. This means that the environment needs to be kept ideal not just for the plant but for insect habitation as well.

The trees itself demand a lot of care and attention. Even if you give it all the TLC it deserves, one tree will only produce between 1kg to 5kg of beans a year. That’s not a lot.

A seedling takes about two months to form from a seed. Once the first shoot has sprouted, the soil must remain moist, but not too moist, and kept away from direct sunlight.

It will take another three years before the tree finally starts bearing fruit and another three years for it to become mature and producing fully.

The good news is, the tree will continue producing those delectable beans for about 25 years.

The beans are green as they grow and turn red once they are fully ripe. Some coffee species have yellow beans when they ripen such as the Yellow Bourbon variety from Brazil.

What comes next is the beans are harvested. There is normally one major harvest a year with the crops being hand-picked, making the whole process very labour intensive and difficult.

Approximately 100 to 200 pounds of coffee cherries can be picked a day if a picker is very adept at their job. Pickers are normally individually paid for their labour based on how much they can collect in a day. The harvest is then set to the processing factory where it will be transformed into the fine powder we know so well.

Processing the ripe cherries must begin as quickly as possible to prevent fruit spoilage. There are two methods to processing the coffee beans.

One is the age-old dry method where the beans are simply spread out on huge surfaces to dry under the sun. The process can take up to several weeks depending on the weather. The goal is to get each batch of coffee cherries moisture content down to 11%.

In the wet method, the pulp from the coffee cherry is removed after harvesting so the bean is dried with only the parchment skin left on. This is done using a machine to separate the skin and pulp from the cherries. The beans are then separated by weight as they are passed through water channels. They then make their way to large water-filled fermentation tanks and are then rinsed before they are ready for drying.

If the beans undergo the wet method, their water content must also be reduced to 11% via drying before they are ready for storage. The beans can be sundried or machine-dried in large, rotating drums. The dried beans, now known as parchment coffee, are stored in jute or sisal bags until they are sent to the mills.

Grading and Sorting are done by size and weight at the mills, and beans are also reviewed for color flaws or other imperfections. Defective beans are removed either by hand or by machinery. Finally, the processed coffee beans are packed again into jute bags and shipped around the world to be ground, steeped and poured into your coffee cups.

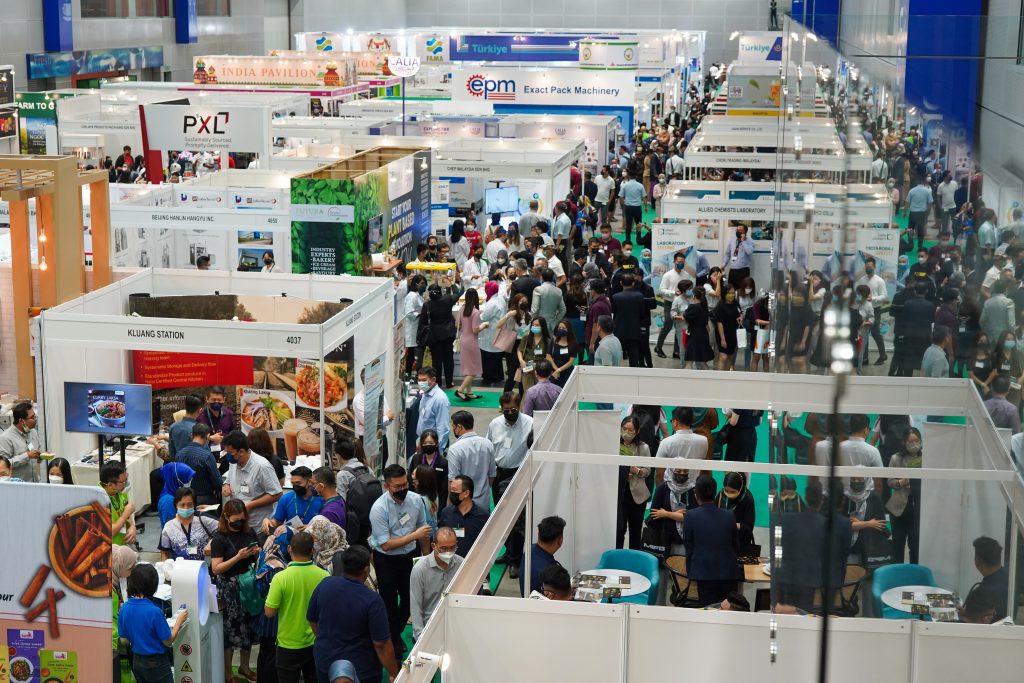

Wondering how the coffee machine and beans work together to creates the best cup of coffee? Visit MIFB 2020 and get advice from our experienced exhibitors.